Table of Contents

*This post may contain affiliate links. As an Amazon Associate we earn from qualifying purchases.

A workbench is the workhorse of your garage. It is a workstation that needs to be strong and sturdy, so when you have to choose a workbench top, it requires some consideration.

You need to be sure the top you choose will match your needs and be an effective option for your desired use. You also want to research material options to give you an idea of what you could use.

This is not something you should make a snap decision about. Take time to get informed and make a calculated decision.

Considerations Before Choosing a Workbench Top

The first thing you need to do before you start to research workbench top options is to consider and define your needs. There are three main points to think about:

- Usage

- Maintenance

- Design

Usage

There are a lot of uses for a workbench. They range from putting together model cars to woodworking to rebuilding an engine. You need to define how you will use the workbench.

Think about the projects you will do. Consider if you will have substances, such as paint and oil, on top of it. Note if you will need something you can pound on or use a saw on. You’ll want to make sure to define the different types of tools you will use on it.

Specifically, you want to think about the damage you might do to a top. If you use a hammer a lot, think about how striking the top could impact it.

Also, consider any type of substance you use that could eat away at a finish you need on the top, such as a finish to prevent moisture.

You need to completely define the activities you will do to determine the material that will best match your intended use. If you do not match the use to the material, you are likely to end up unhappy because the top won’t stand up or may suffer damage.

The way you will use your workbench will weigh greatly in what material you choose for the top because it is all about function. If the top doesn’t match the use, it isn’t going to work.

Recommended Read: 10 Neat Garage Organization Ideas

Maintenance

Maintenance includes making repairs to the top and cleaning it. If you find it important to keep a tidy workspace, then how easy it is to clean will be an important factor.

Some tops are very easy to wipe down, while others may stain easily and require far more work to keep it looking good.

When it comes to maintenance, you have to think about sturdiness. Ideally, you want a very sturdy workbench top because it will enable you to do everything you need without worrying about damage to the table.

Design

Some people don’t care much about how their workbench looks as long as it is functional. However, if you have a nice workspace, such as a newly built garage, you may want to ensure the workbench fits in and looks good.

The design may also come into play if you want special features, such as a flip-top workbench. You will need to choose a top that can function in this way.

Workbench Top Material Options

Once you define your needs, you can begin to check into the various material options. You have three general options for an affordable workbench top material:

- Wood

- Plywood

- MDF

Wood

Wood comes in two options: softwood and hardwood. One of the nice things about wood is that it is easy to find. You also can do a lot with it. It works wonderfully for customization or special designs that you may want, such as a butcher block workbench top.

One thing to note about wood is that it will expand and contract due to weather. It can also take on moisture. Both of these features can lead to warping and damaging unless you do the proper preparation to prevent them. This applies to both soft and hard options.

Softwood

[amazon box=”B01NCNUPFH” template= “horizontal”]

According to Do It Yourself, softwoods are the least expensive wood option. However, as the name suggests, they are easier to damage. If you drop a hard tool, it will dent a softwood top, or if you scrape a tool or part along the top, it will cause damage.

Softwood also may have sap issues because it doesn’t all come out when cutting the wood or even as it sits before you buy it. It can leak out over time, which may lead to some issues.

Examples of softwoods include pine and birch. A birch benchtop can be a better option because it has fewer leakage issues than pine.

Hardwood

[amazon box=”B003L0RVAI” template= “horizontal”]

Hardwood is more durable and heavier than softwood. It can make a nice wood top workbench, but you will pay more for it. In fact, of the three main material options, it is the most expensive.

Another good thing is it should last a long time. It can stand up to anything you need to do on top of it. You should choose your wood carefully. Options such as maple or oak are the best because they are strong, while something like red oak can split more easily.

A maple benchtop, for example, has a really nice look to it. Hardwood is heavy, though, You will either need to use it in strips or keep it very thin.

You can sand down hardwood easily to keep it looking great, but you always want to finish or seal the wood to preserve it and protect it.

You’ll usually be able to find hardwood very easily, more so than softwood tops. If you want something precut, consider an option like the Husky solid wood top workbench.

[amazon fields=”B01MTFC7K9″ value=”thumb” image_size=”large”]

Thick plywood

If you like the idea of wood, but you want something more affordable, you can consider plywood. You can get plywood that looks nice or add a top layer to it. You should consider topping it with something, such as a laminate protective layer.

It is important to note plywood is not very strong. You don’t want to sit an engine on a plywood top because it will crack and break in half.

If your projects will involve heavy items sitting on the workbench, then you should probably skip the plywood or ensure you get a decent thickness to add stability and sturdiness.

On the plus side, it won’t warp, and the weather won’t affect it. It also is rather resistant to damage from pounding on it or using substances. Plus, it is affordable and simple to replace if you need to.

MDF

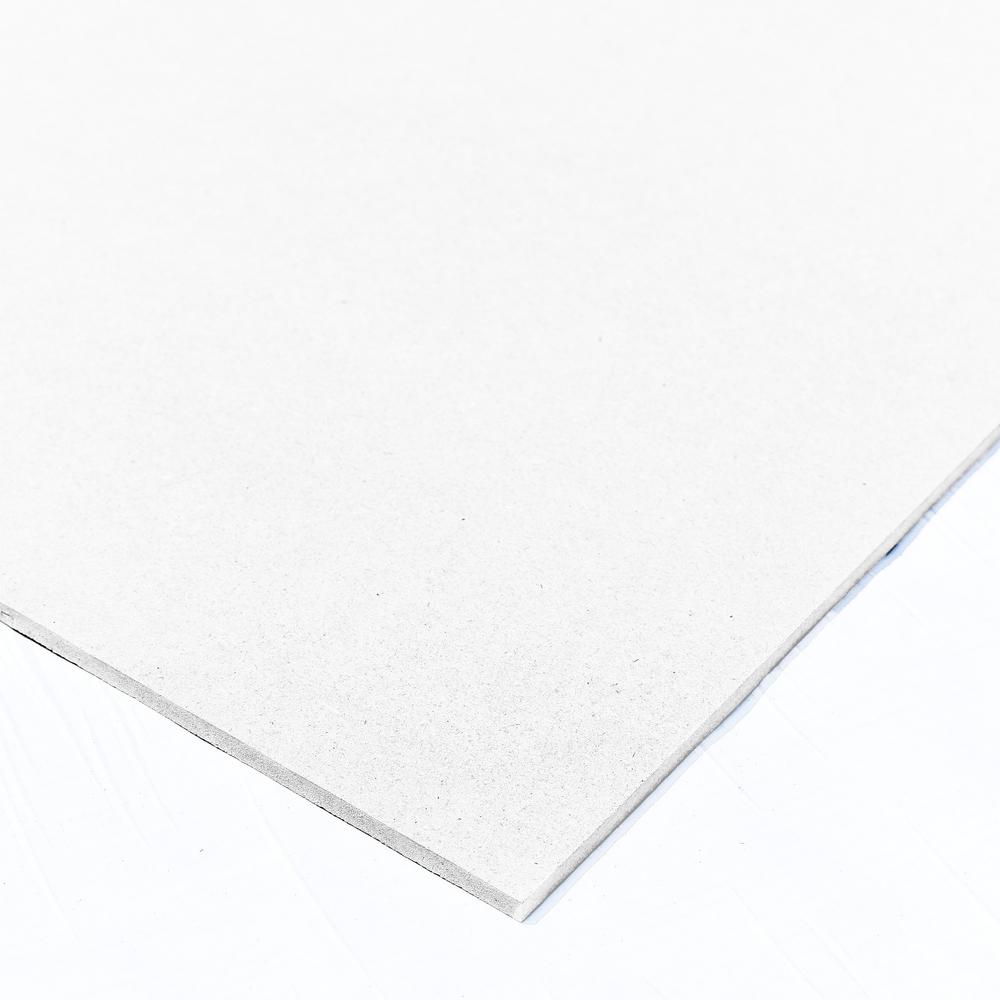

MDF or medium-density fiberboard is similar to plywood, but it uses sawdust and a binder that a machine compresses using pressure. It is probably the least expensive option you have. It is solid and flat.

It does lack strength, so you will have to be careful about damaging it. If you expect heavy use of your workbench, then you probably should choose something else.

You also have to seal it or it will suffer damage. It is prone to issues due to moisture and it will warp if exposed.

It is a nice option if you need to cover a big bench on a budget. It works well with clamps, too. You can customize rather easily. It also is pretty strong throughout the piece, so you can use it if you want to overhang the bench.

Keep in mind that you can add a top layer to MDF that can add strength and durability, so don’t let these characteristics cause you to immediately dismiss it as an option. You should look into the different choices you have before making that decision.

Frequently Asked Questions

Because there are so many things to consider when it comes to choosing the top of your workbench, it might help you to review some of the common questions people ask about this topic.

Here is a look at some frequently asked questions that will address some additional points you want to think about.

How do I attach a workbench top?

The way you attach your workbench top depends largely on what material you use. You can screw down wood with no issue, but you’ll have to be more careful with plywood or MDF because you could damage it.

It also depends on the thickness. You may need more security if you have a very thick top than if you have a thin top.

The main thing to keep in mind when attaching the top is that it has to lie flat and must be secure. If it isn’t flat, it will cause all types of problems for you as you try to work on it.

The last thing you want is a top that moves around, so make sure you securely attach it above all else. A loose top is a security issue that you don’t want to worry about.

What should I use for a workbench top?

There is no perfect material that will work for everyone’s needs the same way. You have to choose the material that best suits you and what will work well for your intended projects.

You can choose a traditional top, such as wood, plywood, or MDF, or you can get creative and try other materials. It is all about finding what suits you the best. You want to ensure it meets all of your requirements and will be a suitable option for you to do your projects on.

How do I protect my workbench top?

You should always add some type of protective layer or sealant to your top. This will protect the material, help prevent damage, and extend its life.

There are many finishes and topper options. Some include Masonite sheets, laminate sheets, finished plywood strips, and finished hardwood strips. You can also apply stain or oil and wax.

Popular Woodworking notes that if you apply a finish to a wood topper, you want to keep it light. Too much finish will not provide a stable surface as it will be too slippery. It could also crack easily if too thick. You want something easy to apply and that can go on thin.

How thick should my workbench top be?

This is a question even those with experience in building workbenches wrestle with. There are a few things to think about when it comes to thickness.

Fine Woodworking explains one of the first considerations is how thickness relates to the weight of the overall top piece. It is imperative to make sure it is not too heavy for your base. You need it to make sense with your base. If it is small and thin, a thick top will not look right and probably will topple the base.

Some materials will work fine at greater thicknesses. For example, MDF is so lightweight, that even if you go really thick, it shouldn’t ever get too heavy. However, if you go too thin, it will be incredibly weak. So, you have to have some thickness.

Wood, on the other hand, gets heavy fast, so you need to stick with thinner wood tops. If you go thicker with wood, then you can sand it down multiple times to clean it up and remove any damage. If it is too thin, you won’t have this option or won’t be able to do it as many times.

There is also a balance to strike between thickness and durability. Thinner tops will not stand up as long as thicker ones no matter what material you use.

General guidelines suggest that with wood you want to stay between 1 ½ to 2 inches. You may get by going to 3 inches, but over that may be too much of a challenge. For plywood and MDF, it is more about matching the thickness to your base than any guidelines for average thickness to use.

Recommended Read: Workbench Plans You Can Easily Follow And Build

Wrapping Up

Choosing a top for your workbench requires taking time to consider every factor. In the end, you want a strong, durable top that will last you for years and allow you to complete your projects without issues. As long as you do your research and think it over, you should be able to make the right choice in the end.